press tiles

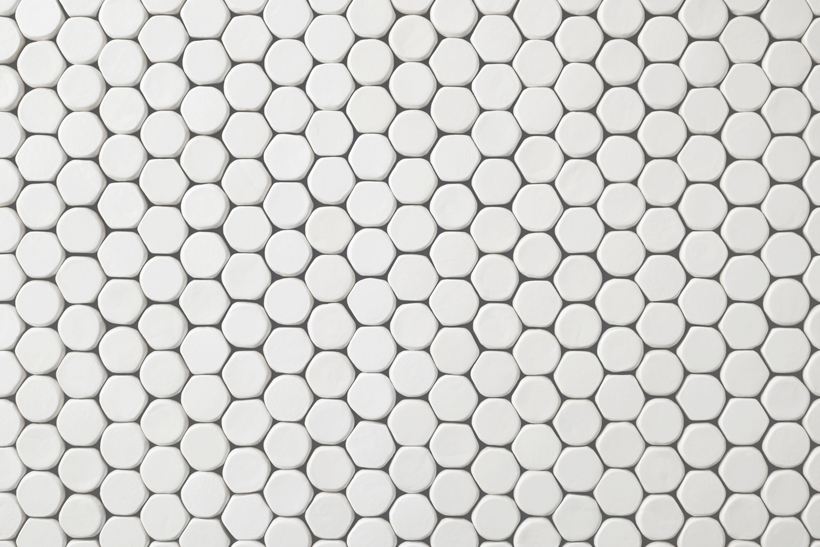

Ceramic tiles are ordinarily produced using molds in order to provide the clay with a smooth uniform shape and finish.

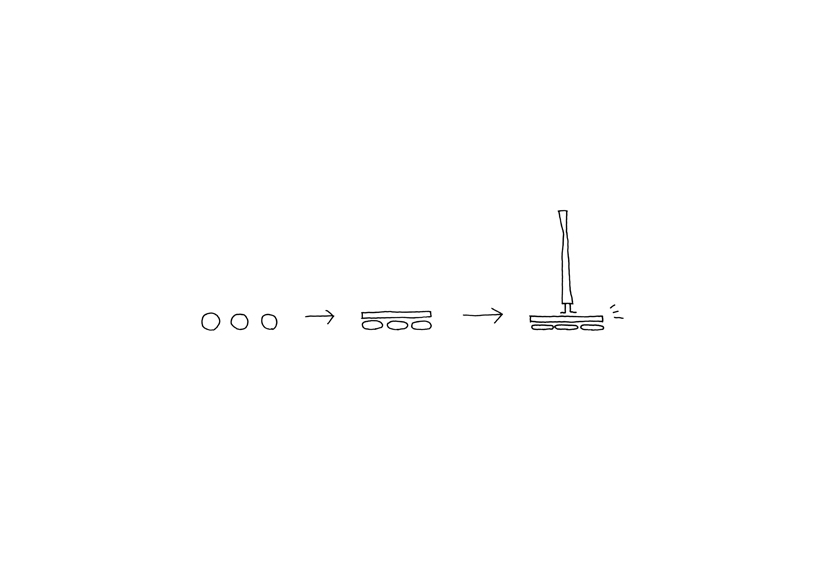

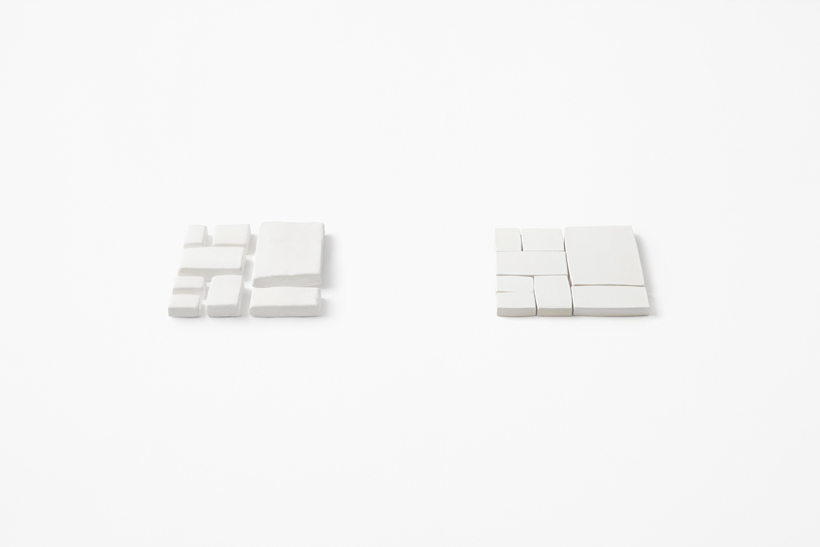

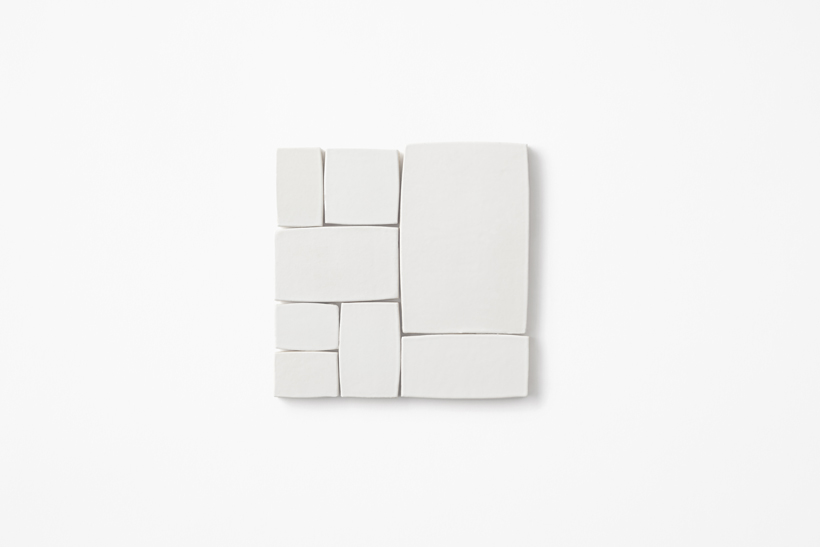

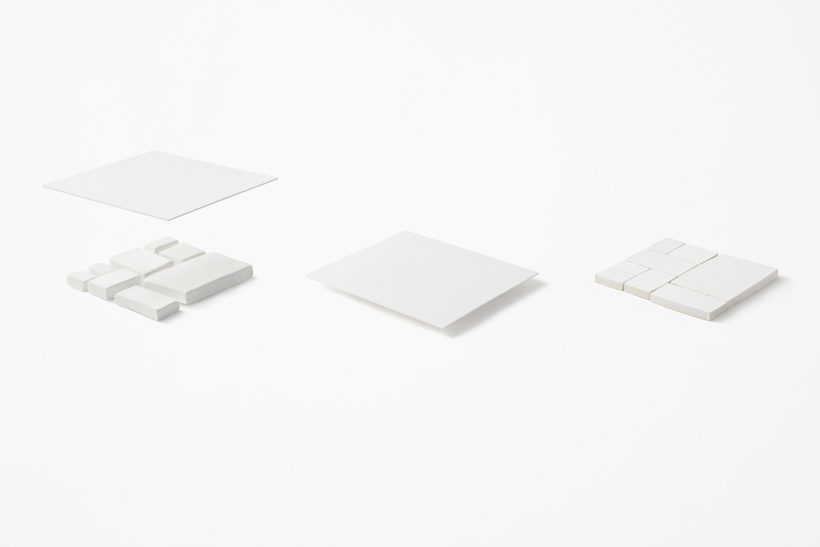

In this project, spheres and cubes shaped clusters of clay were placed in regular intervals, and then pressed under a solid surface to create flat tile forms.

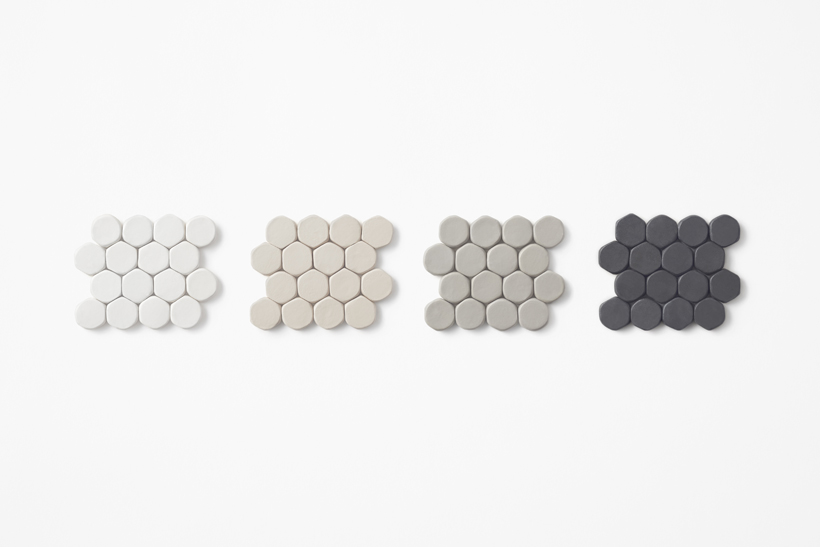

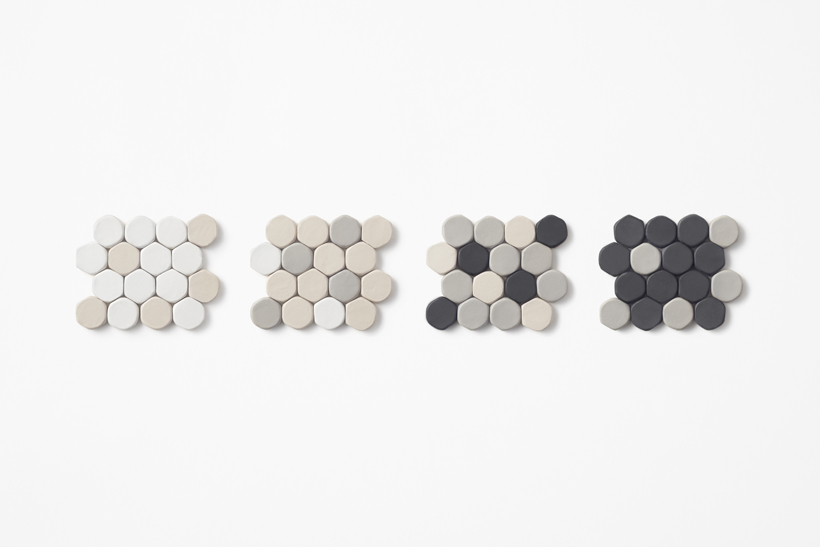

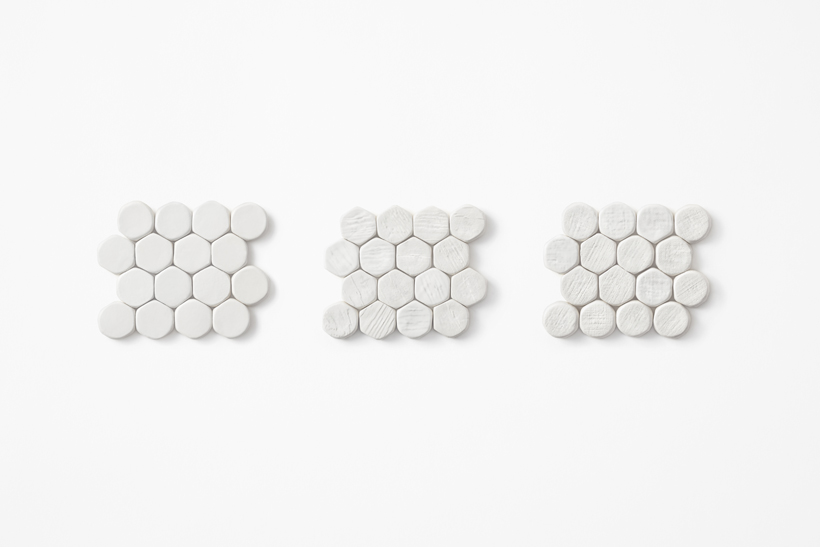

When the clay is being mashed and spread under the surface, the sphere changes its shape to a soft hexagon, while the cubic shape becomes a rectangular form, with a slight bulge out from its center. Due to the unexpected nature of this process, each tile is slightly different than the other, giving a softer feeling to the space they are placed in. With this process it is also possible to add textures on the tile’s surface at the same time it is being formed, by placing materials such as fabric and wood in between the clay and the pressing surface.

The clay mixing balance, the moisture level, the pace of pressure and the right shapes and angles were all tested to enable the best possible outcome, and many tests and prototypes were made to prevent the clay from cracking while being pressed. In the end, it almost felt as if the material itself was the one determining the process and designing the tile shapes for us.