hyouri

Kojima Shouten has been making Kyoto paper lanterns since its founding in the middle of the Edo period(1603-1868 A.D.). Made from beginning to finish by hand, from splitting bamboo to paper pasting, the traditional Kyoto lantern’s defining features are their strength and durability. In utter contrast, the element of suppleness was added to produce a new aspect to the lanterns.

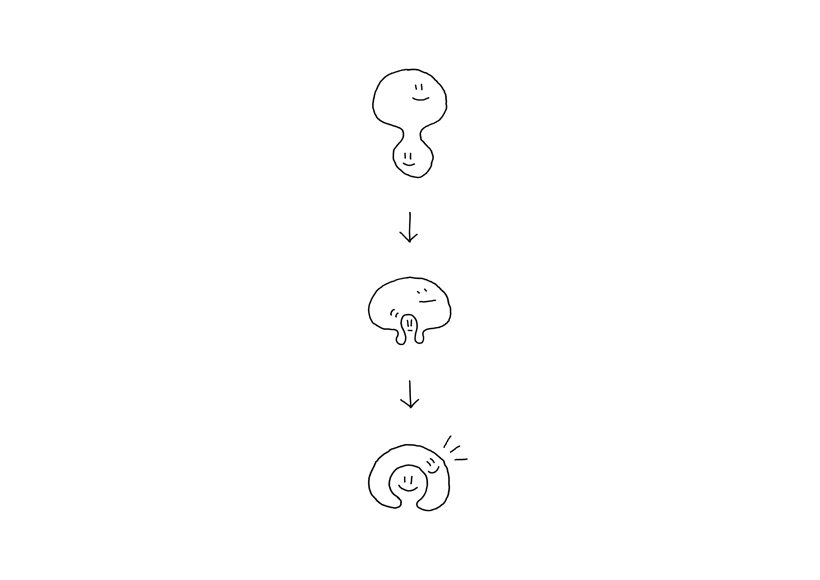

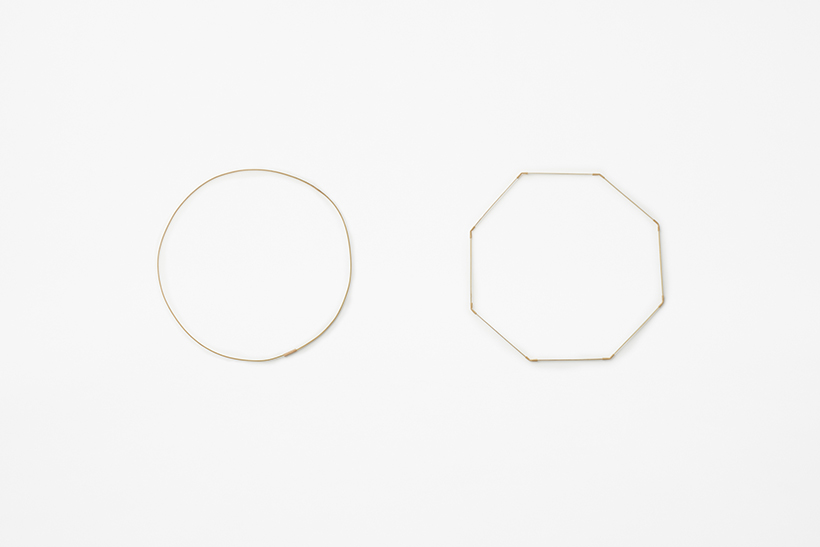

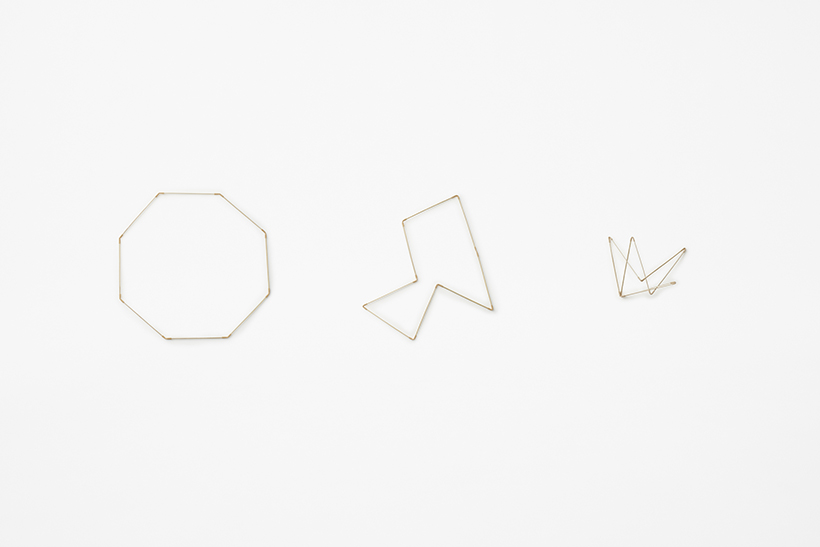

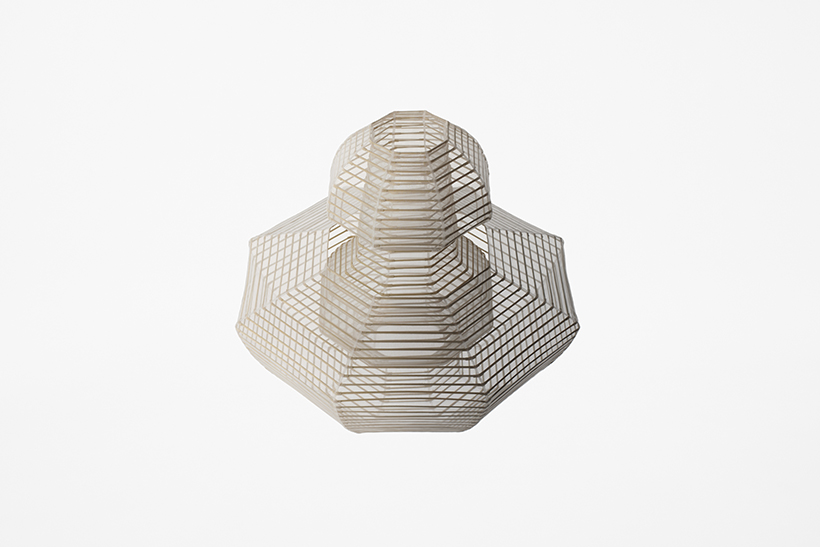

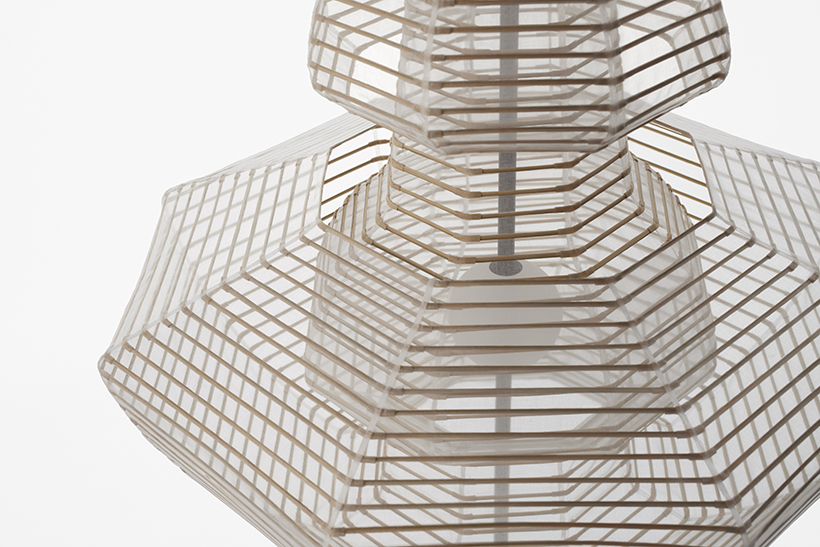

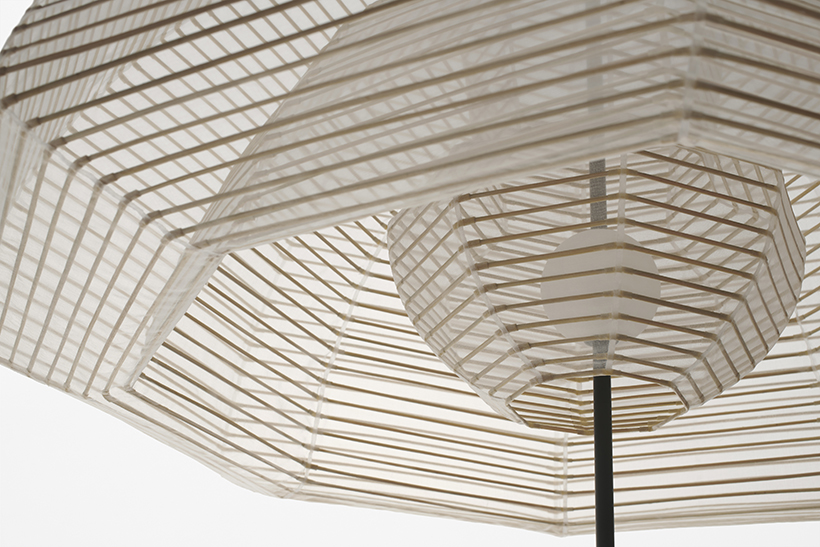

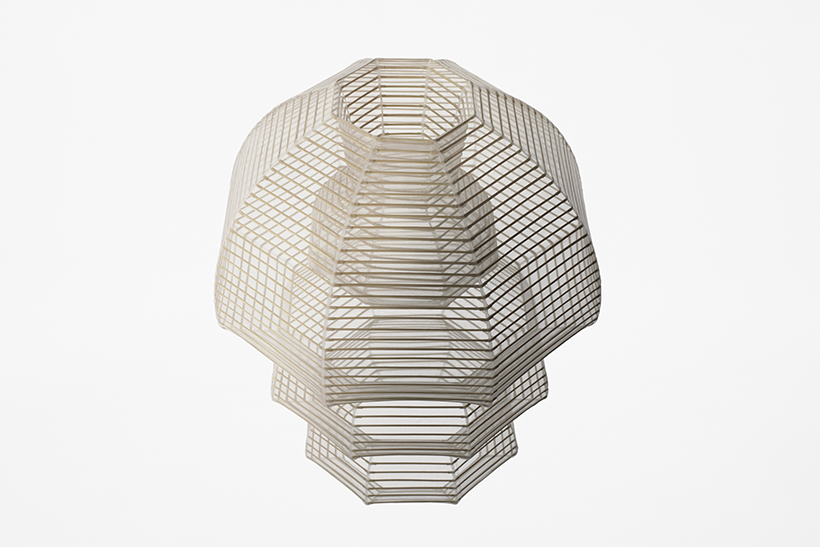

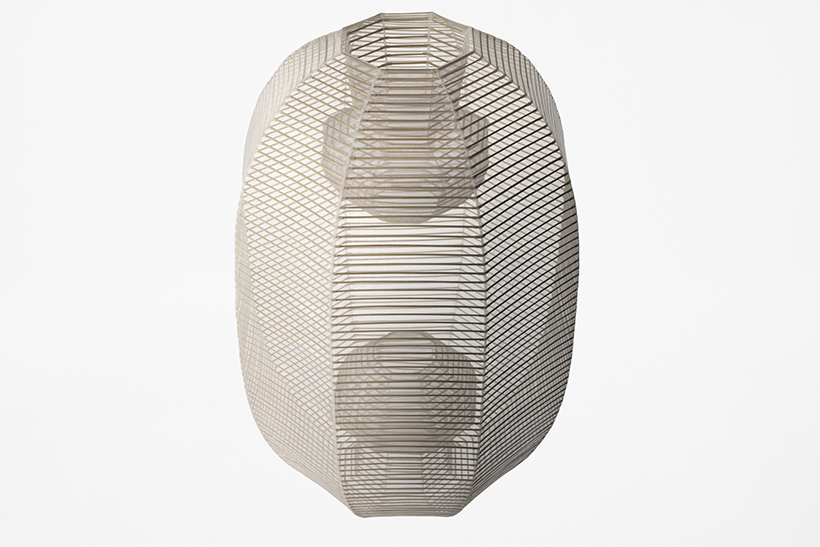

In standard Kyoto lanterns, the ring-shaped bamboo frame functions as the lantern’s bones. A single bamboo strip is shaped into a ring, and after the ends are fixed with washi paper, the loops are fitted into a wooden mold and connected together with thread. With focus on this process, rather than binding the strips tightly to each other, leaving some slack between the strips and binding them with washi paper yielded mobility as if they were joints. Adding eight such joints in the circumference of one ring thus enabled the lantern to be turned inside out.

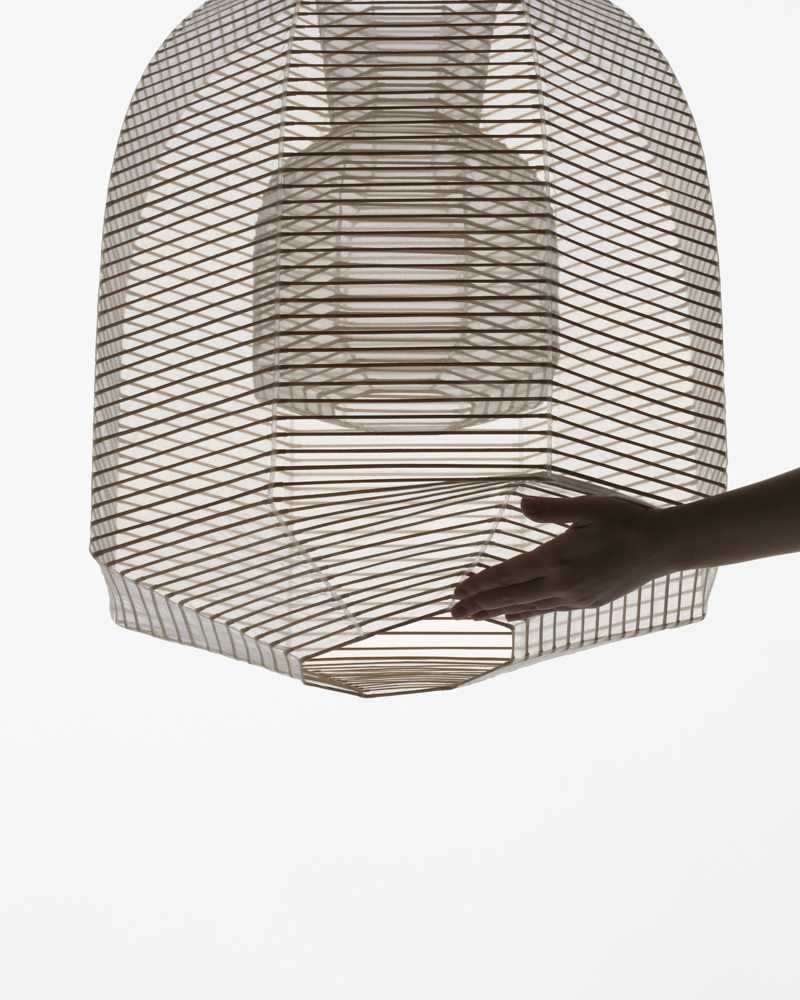

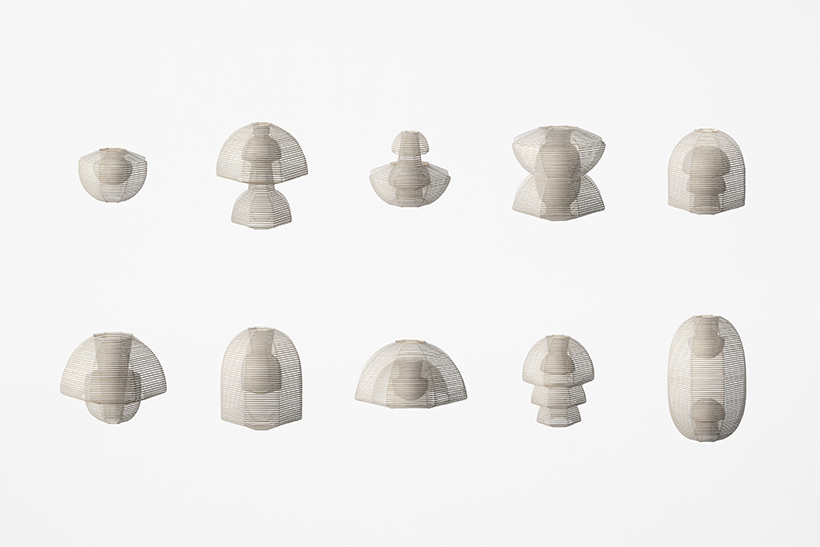

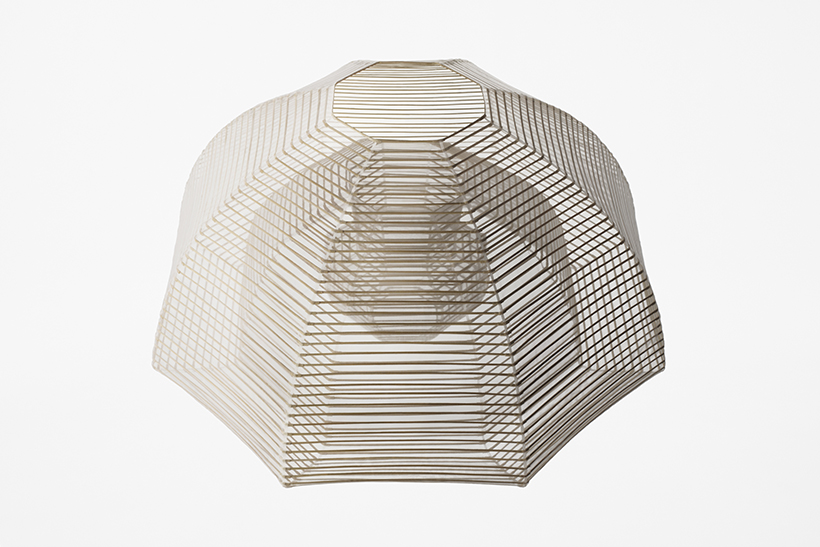

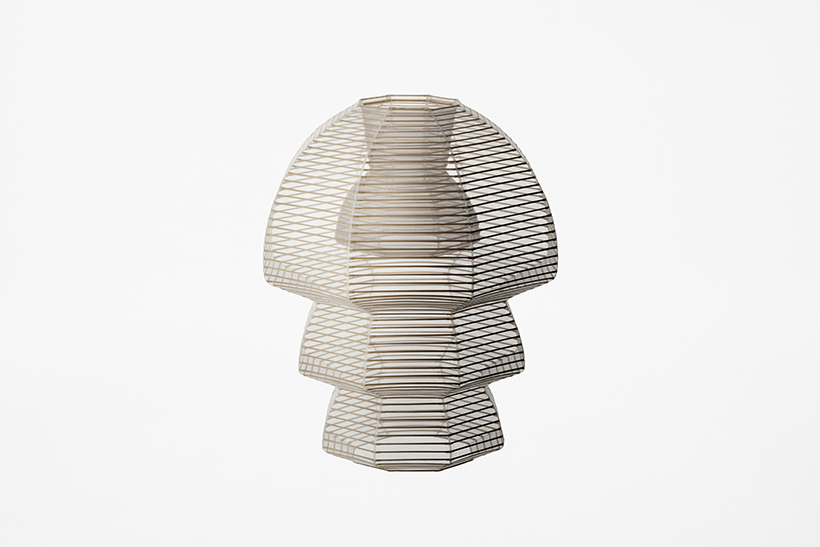

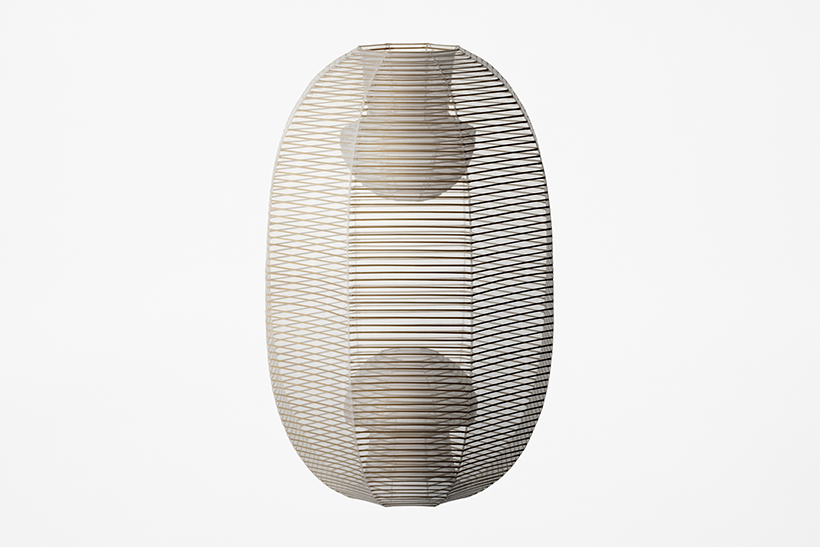

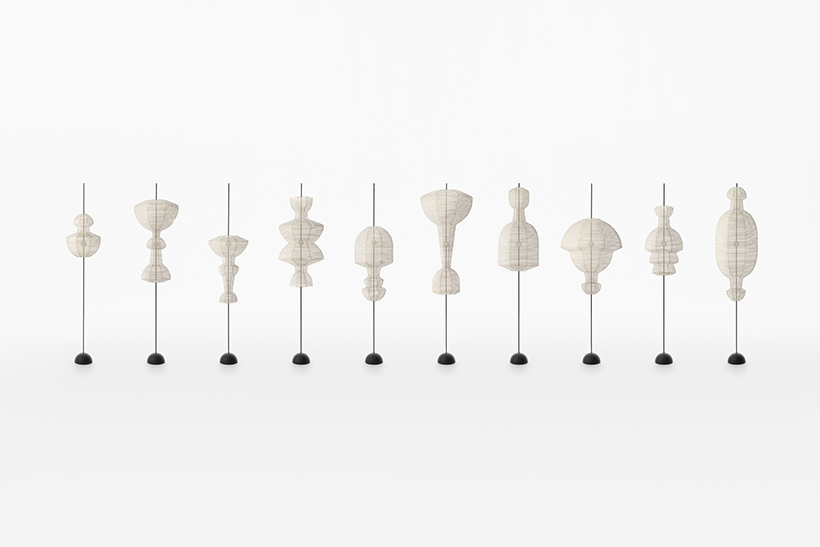

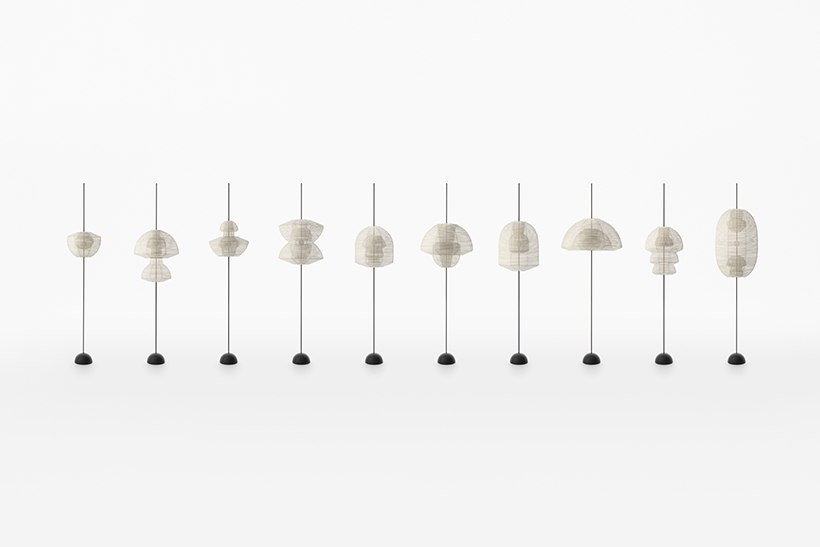

A total of 10 designs were produced, including lanterns seeming to swallow parts of themselves, some triply nested, and some even reaching inward to peak through the other side. Although Kyoto lanterns are often covered with thicker washi paper for outdoor use, hyouri has instead a highly translucent silk lining to leverage its characteristics.

The final product is a light, multilayered lantern expressing the genes of the traditional Kyoto lantern as well as an aspect far from the latter’s unaffected solidness.