foam-can

Beer heads are considered essential for having beer taste better, at least in Japan. It is because a layer of foam with adequate thickness acts as a lid to prevent beer from coming into contact with the air, and keeps it from releasing aroma, flavor, and carbonation. In the domestic beer market, beer for commercial use is usually shipped in bottles or tanks, while most beer for home consumption is canned. In the latter case, however, it is difficult to create an ideal foam when pouring from a can into a glass.

There are two main principles of bubbles that form from canned beer, besides the factor derived from its raw materials: the sudden drop in pressure inside the can when it is opened and the friction that occurs between the can and the liquid when pouring. Through our study, it has been found that if the pull tab doesn’t fully open the can, the pressure is concentrated in the narrow opening. At the same time, when pouring, the area of the beer in contact with the lid increases, which facilitates the formation of bubbles.

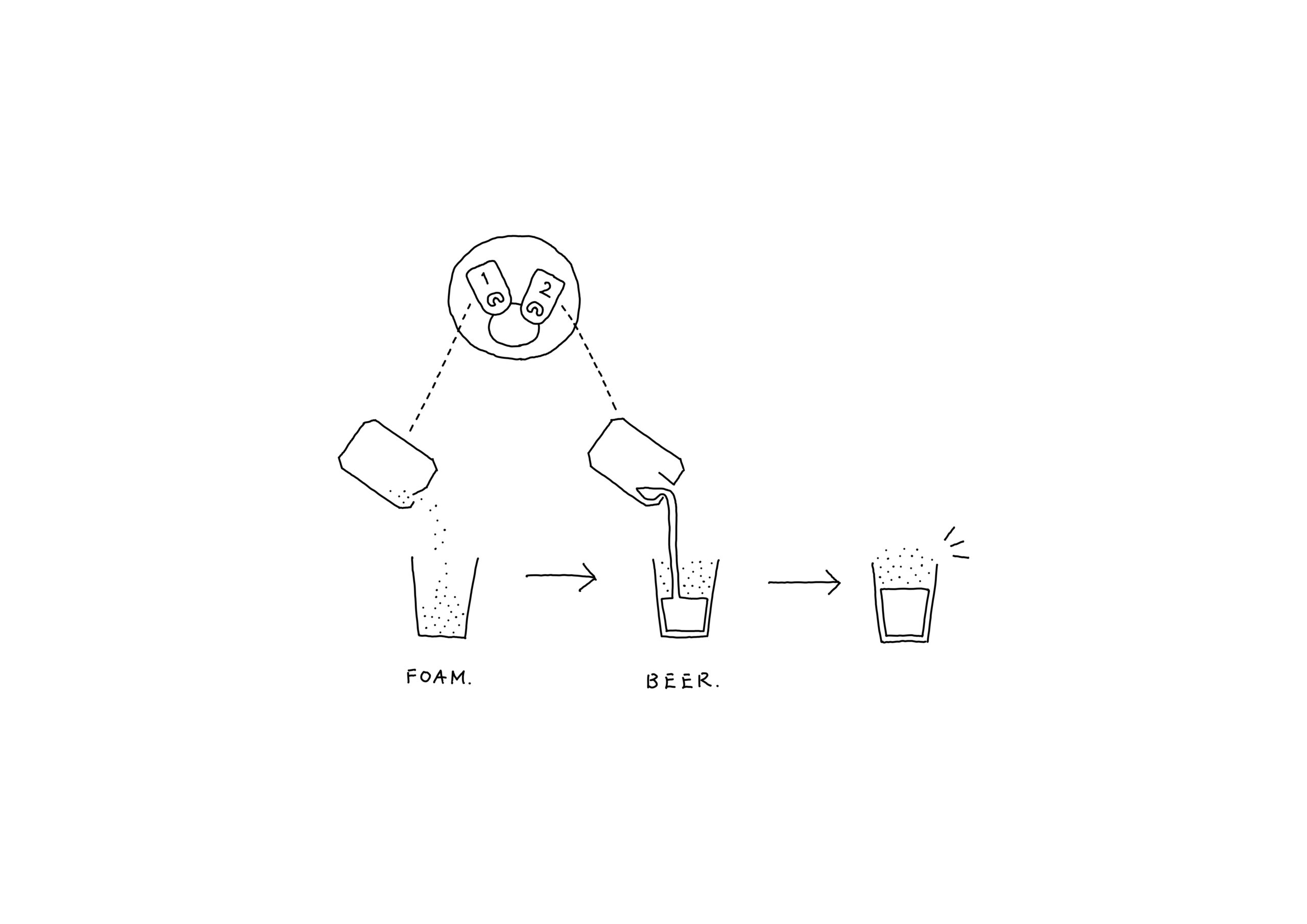

Based on the research, a new can was designed with two pull tabs, which is usually just one in general. Slightly different distances between each pull tab and the lid change the degree of opening. When the can is opened by the first tab, the lid opens a little to create more foam. Once the glass is about half full of bubbles, stop pouring and wait for the bubbles to settle. Then open the second tab, which opens the lid to the fullest, and gently pour the rest under the foam. In this way, a glass with a liquid-foam ratio of 7:3, so-called golden ratio, can now be easily achieved with canned beer.